Selelekela:

Mechini ea ho tjheseletsa sebaka sa betrike disebediswa tsa bohlokwa tlhahisong le kopanong ya dipakete tsa dibetri, haholoholo makaleng a dikoloi tsa motlakase le a matla a ntjhafatswang. Ho utlwisisa molaomotheo wa tsona wa tshebetso le tshebediso e nepahetseng ho ka ntlafatsa haholo bokgoni le boleng ba kopano ya dibetri.

Molao-motheo oa ho Sebetsa oa Mochini oa ho Sebetsa oa ho Tjhesa Sebaka sa Betri

Ho tjheseletsa sebaka sa betri ke mokhoa o kopanyang bokaholimo ba tšepe bo habeli kapa ho feta hammoho ka ho sebelisa mocheso le khatello. Sena se finyelloa ka ho sebelisa motlakase o phallang lipakeng tsa likarolo tsa mosebetsi. Likarolo tsa motheo tsamochini oa ho tjheseletsa libakakenyeletsa:

1. Li-electrode: Tsena hangata li entsoe ka koporo 'me li sebelisetsoa ho tsamaisa motlakase ho thepa e tjheseletsoang. Moralo oa li-electrode o ka fapana ho latela ts'ebeliso e itseng le mofuta oa litšepe tse kopanngoang.

2. Transformer: Transformer e fokotsa motlakase o phahameng ho tloha mohloling oa motlakase ho ea ho motlakase o tlase o loketseng ts'ebetso ea ho tjheseletsa ha e ntse e eketsa motlakase.

3. Sistimi ea Taolo: Mechini ea sejoale-joale ea ho tjheseletsa e na le li-microcontroller tse lumellang taolo e nepahetseng holim'a liparamente tsa ho tjheseletsa, tse kang hona joale, nako le khatello.

Ts'ebetso e qala ha li-electrode li behiloe holim'a libaka tse tla kopanngoa. Joale motlakase o feta ka har'a li-electrode, o hlahisa mocheso ka lebaka la khanyetso ea motlakase sebakeng sa litšepe. Mocheso ona o phahamisa mocheso ho fihlela moo thepa e qhibilihang teng, o etsa hore li kopane. Khatello e sebelisoang ke li-electrode e thusa ho netefatsa tlamo e matla ka ho fokotsa ho thehoa ha li-oxide lenonyellong.

Kamora nako e kgutshwane ya ho phodisa, lenonyeletso le weldilweng lea tiya, e leng se fellang ka kgokelo e matla ya mechini. Tshebetso yohle hangata e potlakile haholo, e nka karoloana feela ya motsotsoana.

Mekhoa ea ho Sebelisa Mochini oa ho Wellisa Sebaka sa Betri

- Litokisetso

Pele o sebelisamochini oa ho tjheseletsa sebaka sa betri, ho bohlokoa ho lokisa sebaka sa mosebetsi le thepa:

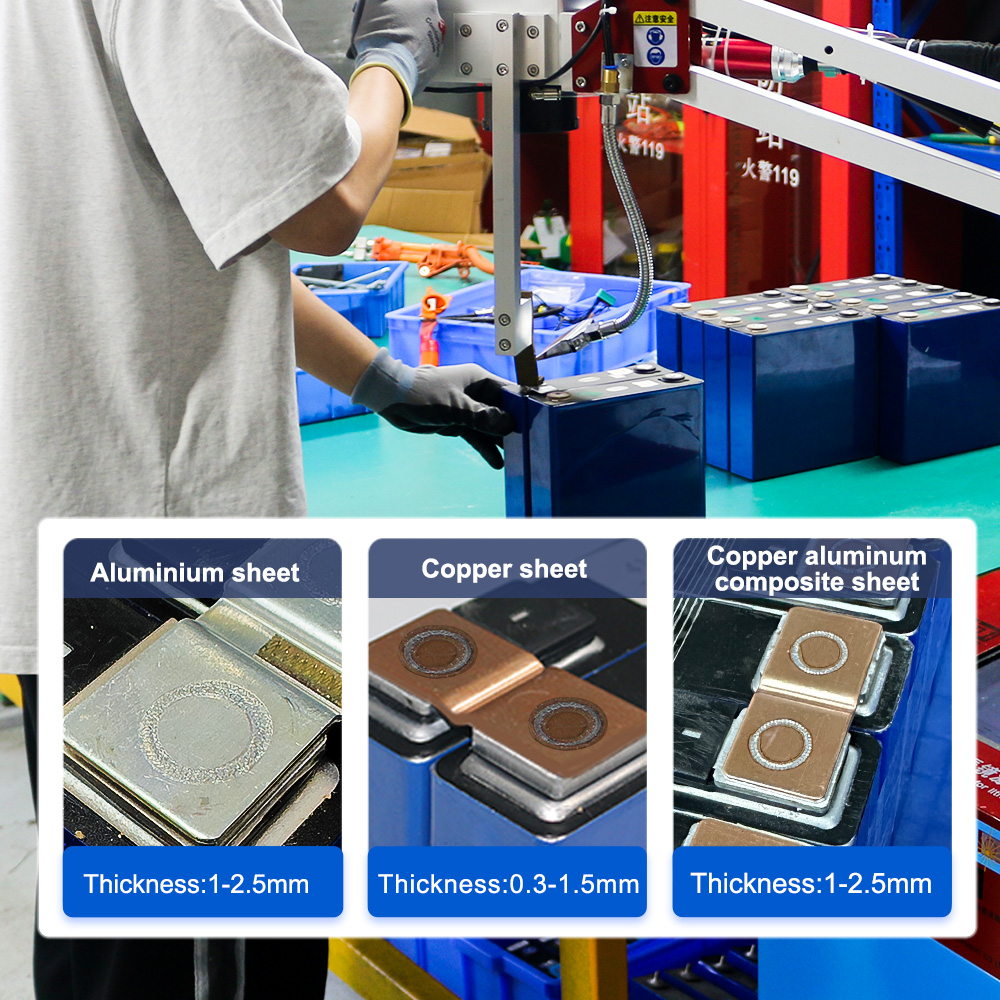

1. Khetho ea Thepa: Netefatsa hore litšepe tse tjheseletsoang lia lumellana. Thepa e tloaelehileng bakeng sa likhokahano tsa betri e kenyelletsa tšepe e koahetsoeng ka nikeli le aluminium.

2. Tlhoekiso ea Bokaholimo: Hloekisa libaka tse tla kopanngoa ho tlosa litšila life kapa life, tse kang mafura, litšila, kapa oxidation. Sena se ka etsoa ka ho sebelisa li-solvent kapa thepa e khorofo.

3. Tlhophiso ea Lisebelisoa: Hlophisa mochini hantle ho latela litaelo tsa moetsi. Sena se kenyelletsa ho lokisa li-electrode le ho netefatsa hore likarolo tsohle tsa polokeho lia sebetsa.

- Mochini oa ho Tjheseletsa oa MathebaMokhoa oa ho tjheseletsa

1. Sebaka: Beha lisele tsa betri le li-strips tse hokelang sebakeng se nepahetseng pakeng tsa li-electrode. Netefatsa hore li hlophisitsoe ho qoba ho se lumellane hantle nakong ea ts'ebetso ea ho tjheseletsa.

2. Litlhophiso tsa Litlhophiso: Fetola liparamente tsa ho tjheseletsa tsamaisong ea taolo, ho kenyeletsoa matla a hona joale, nako ea ho tjheseletsa, le khatello. Litlhophiso tsena li ka fapana ho latela thepa le botenya bo tjheseletsoang.

3. Ho tjheseletsa: Kenya mochine tshebetsong ho qala tshebetso ya ho tjheseletsa. Lekola tshebetso ho netefatsa hore di-electrode di boloka kgokagano e nepahetseng le hore motlakase o phalla hantle.

4. Tlhahlobo: Kamora ho tjheseletsa, hlahloba manonyeletso ka mahlo bakeng sa diphoso leha e le dife, tse kang ho kopana ho sa fellang kapa ho fafatsa ho feteletseng. Ditshebediso tse ding di ka hloka tlhahlobo e eketsehileng bakeng sa ho tswela pele ha motlakase kapa matla a mechini.

Mehopolo ea Polokeho

Ho sebetsa lemechine ea ho tjheseletsa libakae ka baka likotsi tse itseng. Kamehla latela melaoana ea polokeho:

1. Lisebelisoa tsa ho Sireletsa: Apara lisebelisoa tse loketseng tsa ho itšireletsa (PPE), ho kenyeletsoa liatlana, likhalase tsa tšireletso le liaprone ho itšireletsa khahlanong le litlhase le mocheso.

2. Phefumoloho: Netefatsa hore sebaka sa mosebetsi se na le moea o kenang hantle ho qoba ho hema mosi ofe kapa ofe o hlahisoang nakong ea ts'ebetso ea ho tjheseletsa.

3. Mekhoa ea Maemo a Tšohanyetso: Itloaetse mekhoa ea ho koala mochini ka tšohanyetso 'me u netefatse hore mochini o na le libaka tsa ho emisa tsa tšohanyetso tse fumanehang habonolo.

Qetello

Mechini ea ho tjheseletsa sebaka sa betriba bapala karolo ea bohlokoa ho kopanyeng ka katleho lipakete tsa libeteri. Ho utloisisa molao-motheo oa bona oa ts'ebetso le ho latela mekhoa e nepahetseng ea ts'ebeliso ho ka lebisa ho li-weld tsa boleng bo holimo le tlhahiso e ntlafetseng. Ka ho beha polokeho le boitokiso pele, basebetsi ba ka sebelisa mechini ena ka katleho lits'ebetsong tse fapaneng, ba kenya letsoho ntlafatsong ea mahlale a polokelo ea matla.

Haeba o na le mohopolo oa ho kopanya betri ka bouena, haeba o batla sesebelisoa sa ho tjheseletsa betri ka nepo e phahameng, joale sesebelisoa sa ho tjheseletsa betri se tsoang ho Heltec Energy se loketse ho nahanoa.

Haeba o na le lipotso kapa o ka rata ho tseba ho eketsehileng, ka kopo o se ke oa tsilatsila hoikopanye le rona.

Kopo ea Khoteshene:

Jacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Nako ea poso: Loetse-20-2024