Selelekela:

Betri ea Lithiumke betri e tjhajwang hape e nang le lithium e le karolo ya bohlokwa. E sebediswa haholo disebedisweng tse fapaneng tsa elektroniki le dikoloing tsa motlakase ka lebaka la matla a yona a mangata, boima bo bobebe le bophelo ba potoloho e telele. Mabapi le tshebetso ya dibetri tsa lithium, ha re shebeng mekgwa ya ho tjheseletsa di-spot, ho baka ka hara motheo le ho enta ka metsi dibetri tsa lithium.

Ho tjheseletsa libaka

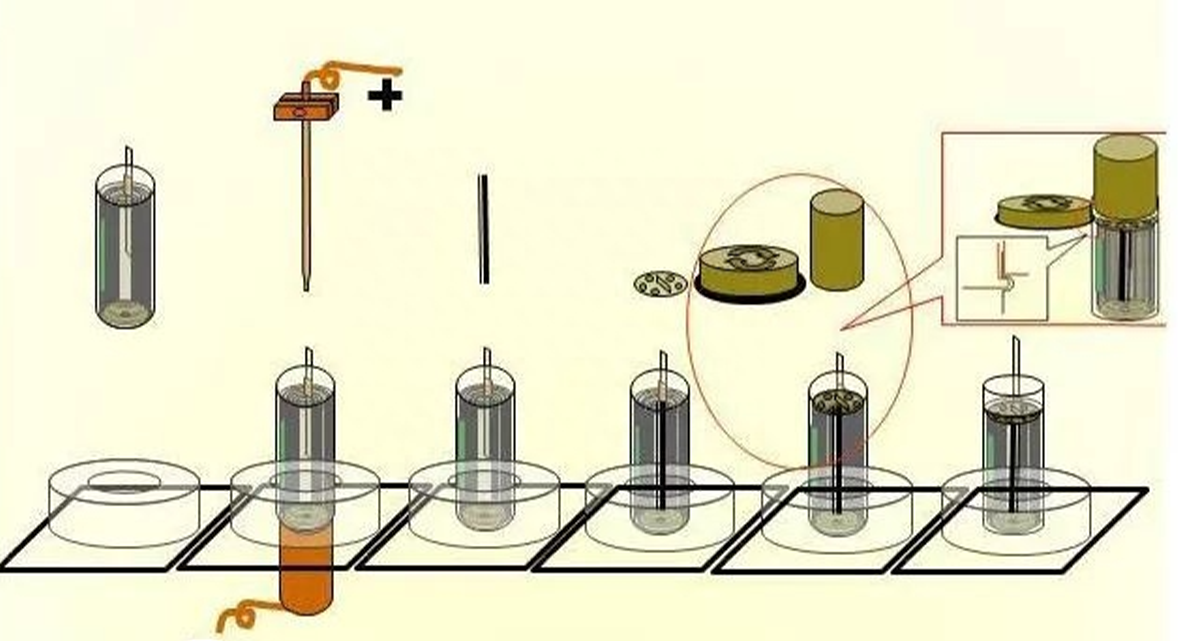

Ho tjheseletsa pakeng tsa dipalo tsa dibetri tsa lithium le pakeng tsa dipalo le mokhanni wa electrolyte ke e nngwe ya ditshebetso tsa bohlokwa tlhahisong ya dibetri tsa lithium. Molao-motheo wa yona o ka sehloohong ke ho sebedisa arc ya pulse e nang le maqhubu a hodimo ho kenya motlakase o phahameng le o phahameng wa motlakase o potlakileng pakeng tsa palo le mokhanni wa electrolyte, e le hore electrode le loto di qhibilihe kapele mme di thehe kgokelo e tiileng. Nakong ya tshebetso ya ho tjheseletsa, diparamitha tsa ho tjheseletsa tse kang mocheso wa ho tjheseletsa, nako, kgatello, jj. di hloka ho laolwa ka thata ho netefatsa boleng ba ho tjheseletsa.

Ho tjheseletsa libakake mokhoa oa setso oa ho tjheseletsa 'me hajoale ke mokhoa o sebelisoang haholo oa ho tjheseletsa. Ho sebelisoa molao-motheo oa ho futhumatsa ka ho hanyetsa, thepa ea ho tjheseletsa e futhumatsa le ho qhibiliha ka lebaka la tšebelisano ea motlakase le khanyetso, e leng se etsang khokahano e matla. Ho tjheseletsa ha libaka ho loketse ho etsoa ha likarolo tse kholo tsa betri, joalo ka libeteri tsa koloi ea motlakase, libeteri tsa polokelo ea matla, jj.

Ho baka lisele tsa betri

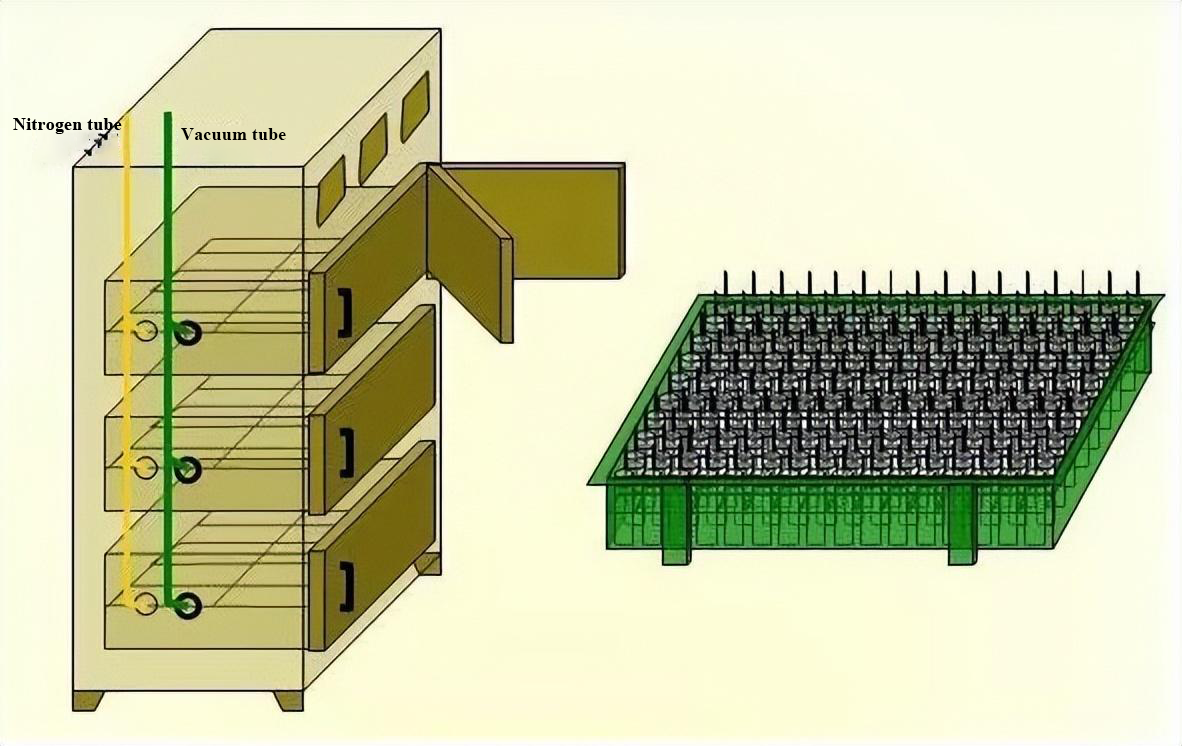

Ho baka ho bapala karolo ea bohlokoa tlhahisong eabetri ea lithiumlisele. Metsi a mangata ka mora ho baka a ama ka ho toba tshebetso ya motlakase. Mokgwa wa ho baka o etsahala kamora kopano e bohareng le pele ho ente ya metsi le ho paka.

Mokhoa oa ho baka ka kakaretso o sebelisa mokhoa oa ho baka ka vacuum, o pompa sekoti ho ea khatellong e mpe, ebe o futhumatsa mocheso o itseng bakeng sa ho baka ka insulation. Mongobo o ka hare ho electrode o hasana ho ea holim'a ntho ka phapang ea khatello kapa phapang ea mahloriso. Limolek'hule tsa metsi li fumana matla a lekaneng a kinetic holim'a ntho, 'me ka mor'a ho hlōla khoheli ea limolek'hule, li baleha khatellong e tlase ea kamore ea vacuum.

Ente

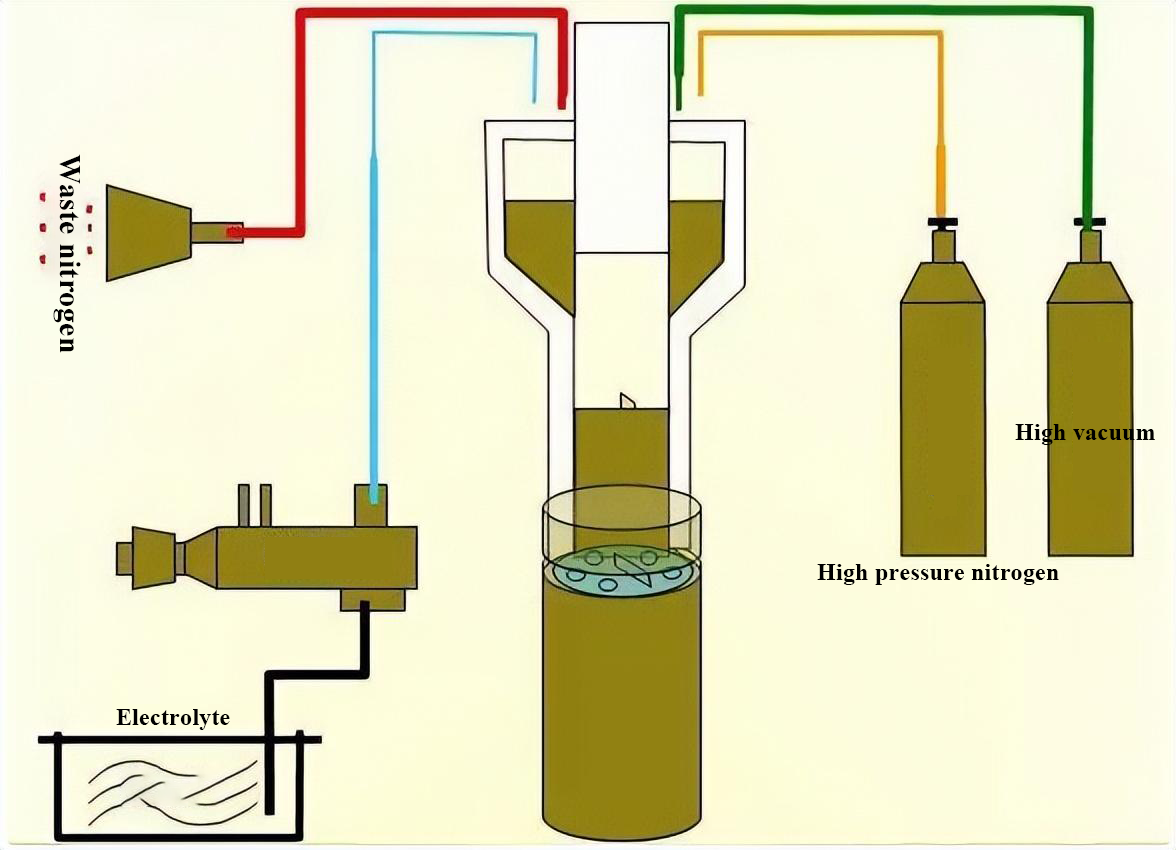

Karolo eabetri ea lithiumelectrolyte ke ho tsamaisa li-ion pakeng tsa li-electrode tse ntle le tse mpe, le ho sebetsa e le mokhoa oa ho tjhaja le ho ntša, joalo ka mali a motho. Mosebetsi oa electrolyte ke ho tsamaisa li-ion, ho netefatsa hore li-ion li tsamaea ka lebelo le itseng pakeng tsa li-electrode tse ntle le tse mpe nakong ea ts'ebetso ea ho tjhaja le ho ntša betri, ka hona ho theha selika-likoe sohle sa potoloho ho hlahisa hona joale.

Ho enta ho na le tshusumetso e kgolo tshebetsong ya sele ya betri. Haeba electrolyte e sa kenngwa hantle, e tla baka tshebetso e mpe ya potoloho ya sele ya betri, tshebetso e mpe ya sekgahla, le ho tjhaja lithium deposition. Ka hona, kamora ho enta, ho hlokahala hore e eme mochesong o phahameng ho dumella electrolyte ho kena ka botlalo electrode.

Mokhoa oa tlhahiso ea ente

Ho enta ke ho ntsha betri pele le ho sebedisa phapang ya kgatello pakeng tsa kahare le kantle ho sele ya betri ho kganna electrolyte ka hara sele ya betri. Ho enta ka Isobaric ke ho qala ka ho sebedisa molaomotheo wa kgatello e fapaneng ho kenya mokelikeli, ebe o fetisetsa sele ya betri e kentsweng setshelong se nang le kgatello e phahameng, mme o pompe kgatello e mpe/e ntle setshelong bakeng sa potoloho e sa fetoheng.

Heltec e fana ka mefuta e fapaneng ea ts'ebetso e phahamengba ho tjheseletsa mathebaE etselitsoe ho tjheseletsa tšepe ea betri ka ho khetheha. Ka ho sebelisa theknoloji e tsoetseng pele ea ho tjheseletsa e hanyetsang, e na le lebelo le potlakileng la ho tjheseletsa le matla a holimo a ho tjheseletsa, e loketse libeteri tsa ho tjheseletsa le lihlahisoa tsa elektroniki. E hlomelitsoe ka sistimi e bohlale ea taolo, basebelisi ba ka fetola habonolo liparamente tsa ho tjheseletsa ho netefatsa boleng bo tsitsitseng ba ho tjheseletsa. Letoto la rona la li-spot welders li nyane ebile li bonolo ho li sebelisa, li thusa ho ntlafatsa katleho ea tlhahiso le ho fokotsa tšebeliso ea matla. Re khethe ho u thusa ho fihlela litharollo tse sebetsang tsa ho tjheseletsa!

Qetello

Mohato o mong le o mong hobetri ea lithiumTs'ebetso ea ts'ebetso e hloka ho laoloa ka thata ho netefatsa polokeho le ts'ebetso ea sehlahisoa sa ho qetela. Ka tsoelo-pele ea theknoloji, lik'hamphani tse ngata le tsona li ntse li hlahloba lisebelisoa le lits'ebetso tse ncha khafetsa ho ntlafatsa bongata ba matla le bophelo ba ts'ebeletso ea libeteri.

Heltec Energy ke molekane oa hau ea tšepahalang tlhahisong ea liphutheloana tsa betri. Ka ho tsepamisa maikutlo ha rona ho sa feleng lipatlisisong le nts'etsopele, hammoho le mefuta e mengata ea lisebelisoa tsa betri, re fana ka litharollo tsa sebaka se le seng ho fihlela litlhoko tse ntseng li fetoha tsa indasteri. Boitlamo ba rona ba bokhabane, litharollo tse etselitsoeng uena, le likamano tse matla tsa bareki li re etsa khetho e ntle bakeng sa bahlahisi le bafepedi ba liphutheloana tsa betri lefatšeng ka bophara.

Haeba o na le lipotso kapa o ka rata ho tseba ho eketsehileng, ka kopo o se ke oa tsilatsila hoikopanye le rona.

Kopo ea Khoteshene:

Jacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Nako ea poso: Pulungoana-01-2024