Selelekela:

Rea u amohela ho semmusoMatla a Heltecblog ea indasteri! Re hlahisitse molao-motheo oa ts'ebetso le ts'ebeliso eaho tjheseletsa sebaka sa betrimochini sehloohong se fetileng, joale re tla tsoela pele ho hlahisa likarolo le ts'ebeliso eamechine ea ho tjheseletsa ea polokelo ea matla ea capacitorka botlalo, ho u thusa ho fumana lintlha tse ling mabapi le sesebelisoa sa ho weldera sa betri le ho khetha se loketseng ka ho fetisisa bakeng sa hau!

Molao-motheo oa Motheo:

Ho tjheseletsa sebaka sa polokelo ya matla a capacitive ho sebedisa di-capacitor ho boloka matla. Ha matla a qhibilihisa sebaka se senyenyane sa lenonyello la solder, capacitor e tla ntsha metsi hanghang. Ha e bapiswa le mekgwa e meng ya ho tjheseletsa jwalo ka mechini ya AC, ho e sebedisa ho tswa ho gridi ya motlakase ho na le matla a tlase a hanghang, mojaro o leka-lekaneng maemong ohle, matla a phahameng, mme ho ka fana ka matla a kopaneng sebakeng sa ho tjheseletsa. E ka fumana dikarolo tse tjheseditsweng tse nang le boleng bo botle ba bokahodimo le phetoho e nyane, mme e ka tjheseletsa tse ding tse thata ho tjheseletsa ditshipi tse seng tsa ferrous ka motlakase o motle.

Mochini oa ho tjheseletsa oa capacitor spot o na le likarolo tsa mechini le tsa motlakase, 'me taolo ea potoloho ke karolo ea bohlokoa ea theknoloji ea ho tjheseletsa ea khanyetso. Theknoloji ea ho theha pulse ea ho bokella matla e laoloang ke theknoloji ea microcomputer chip tšimong ea ho tjheseletsa e pharaletse haholo 'me e se e le karolo ea bohlokoa ea nts'etsopele ea litsamaiso tsa taolo ea mochini oa ho tjheseletsa.

Kopo e ka Sehloohong:

1. Tokiso le ho tjheseletsa ka potlako dipakete tsa betri tsa lithium iron phosphate kapa dipakete tsa betri tsa ternary lithium tse sebediswang dikoloing tsa motlakase, difofaneng tse se nang bapalami, disebediswa tsa motlakase, disebediswa tsa motlakase, diroboto le disebediswa tse ding.

2. Ho tjheseletsa ka potlako dipalo tsa koporo/aluminiamo bakeng sa disele tse kgolo tse fapaneng tse matla.

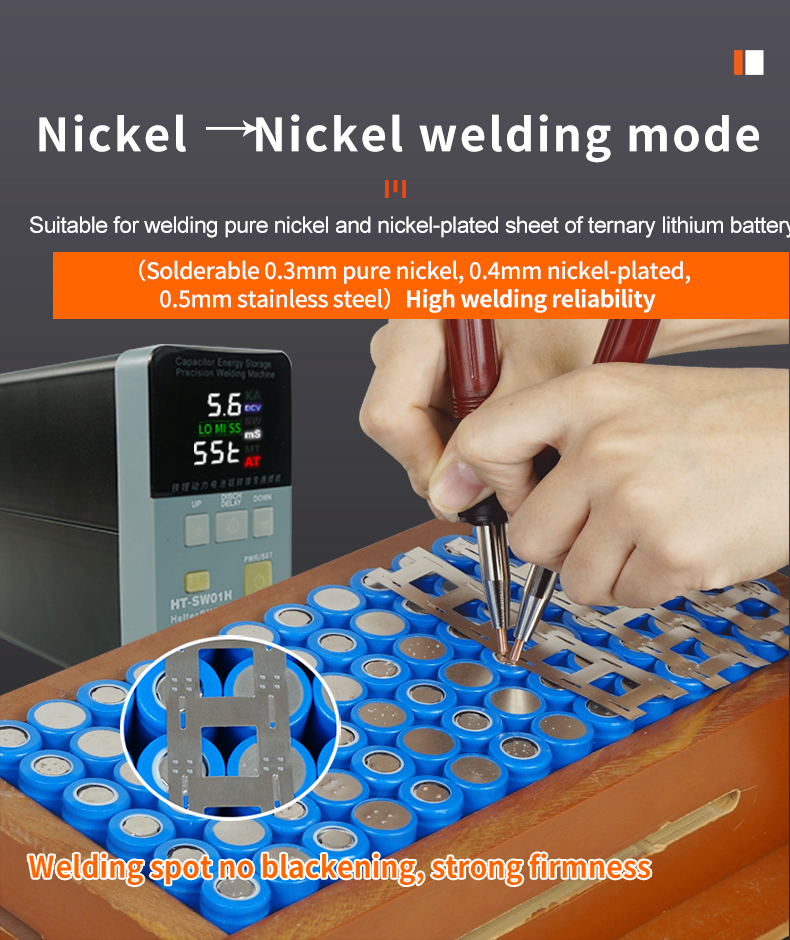

3. Ho tjheseletsa maqephe a kgokelo ya betri (leqephe la koporo le manehilweng ka nikeli / nikeli e hlwekileng / koporo e hlwekileng / leqephe la koporo le manehilweng ka nikeli), dikarolo tsa hardware, dithapo, jj.

4. Lisebelisoa tsa ho tjheseletsa tse kang koporo, aluminium, motsoako oa aluminium oa nickel, nickel e hloekileng, poleiti ea nickel, tšepe e sa hloekang, tšepe, molybdenum, titanium, jj.

Likaroloana:

-

Lebelo le potlakileng:

Ka kakaretso, ho tjheseletsa ho ka phethelwa ka dimilimithara tse makgolo a mmalwa feela. Bakeng sa mosebetsi o nang le bokgoni bo phahameng ba tlhahiso, ho tjheseletsa ka bokgoni ho loketse haholoanyane;

-

Mocheso o phahameng:

ho sebediswa ho tjheseletsa ka capacitor hobane mokgwa wa ho futhumatsa wa ho tjheseletsa ka capacitor ke ho futhumatsa ka induction, kahoo bokahodimo ba karolo e itseng bo ka fihlella mocheso o phahameng ka nako e kgutshwane;

-

Ho tjheseletsa ka mokhoa o tšepahalang:

Boleng ba manonyeletso a solder ho manonyeletso a capacitor boa tšepahala, 'me botsitso ba manonyeletso a solder bo ke ke ba angoa ke mabaka a kantle.

Sehlahisoa sa Rona:

Mechini ea ho tjheseletsa ea polokelo ea matla a Capacitor

Lihlahisoa tsa rona li sebelisa Super Farad Capacitors e le mehloli ea matla a ho tjheseletsa, theknoloji ea tlhahiso ea motsoako o nang le tahlehelo e tlase, le theknoloji e tsoetseng pele ea ho tjheseletsa ka laser, e ka fihlelang letoto la melemo e kang tšebeliso e tlase ea matla, ho se sitisoe ke matla, tlhahiso ea pulse ea matla a mangata, ho tjheseletsa ka botšepehi bo phahameng, le ts'ebetso e ntle ea ho tjheseletsa. E fana ka motheo o motle le o tšepahalang bakeng sa khetho ea lisebelisoa bakeng sa tlhokomelo ea betri ea mohala oa thekeng, tlhokomelo ea betri ea laptop, le tlhahiso le kopano ea banka ea motlakase.

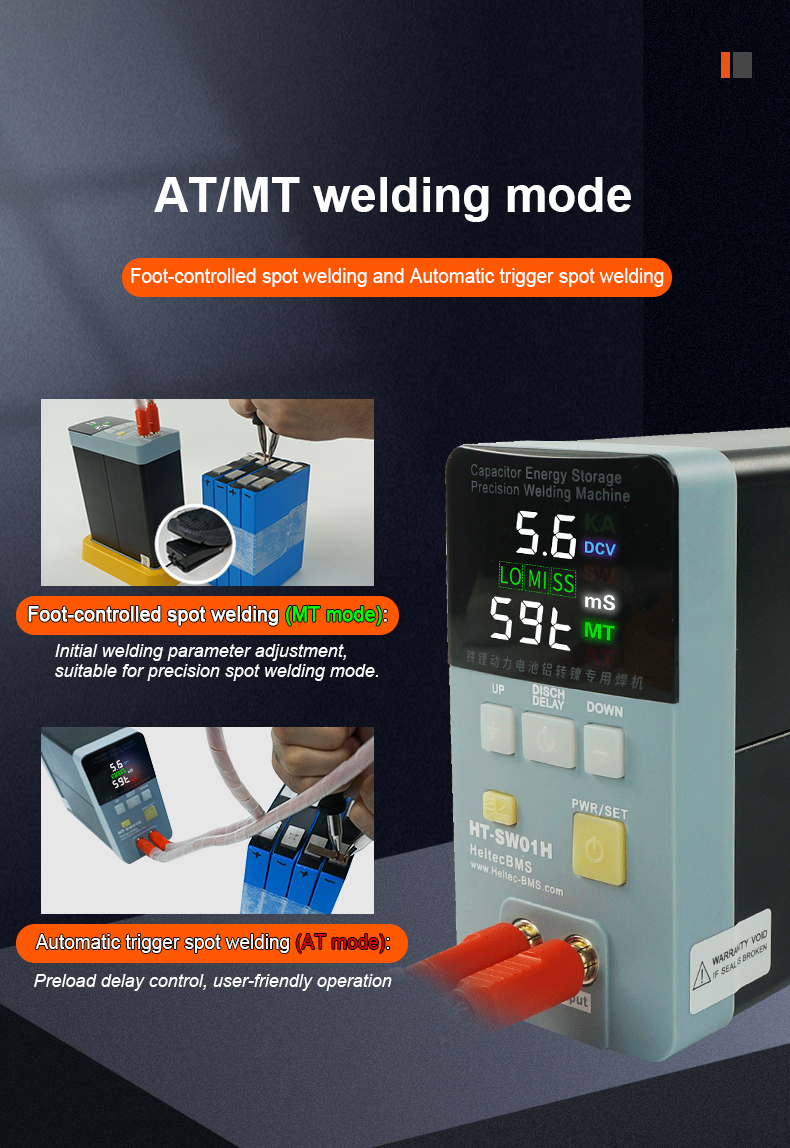

Mechini ea ho tjheseletsa ea Heltec SW01 le SW02 letoto ke mechini ea ho tjheseletsa ea polokelo ea capacitor. Ke li-welder tsa li-spot tse nang le matla a phahameng a ho tjheseletsa a 42KW. U ka khetha motlakase oa peak ho tloha ho 2000A ho isa ho 7000A. Ho bonolo hore u sebelise mokhoa o nepahetseng oa ho tjheseletsa oa li-spot ka senotlolo sa ts'ebetso ea mokhoa o habeli ho tsona. U ka lekanya khokahano e hanyetsanang ka thoko ka sesebelisoa sa ho leka ho hanyetsa sa micro-ohm ka nepo. Li ka fokotsa matla a mosebetsi le ho ntlafatsa katleho ka ho ntša AT induction ka boiketsetso ka ho iketsa. Ka skrine ea 'mala oa LED ho tsona, ho bonolo hore u bone liparamente.

Sehlahisoa | Matla | Lisebelisoa tse Tloaelehileng tsa ho Tjhesetsa | Thepa le botenya (MAX) | Mofuta oa Betri o Sebetsang |

| HT-SW01A | 10.6KW | Pene ea ho tjheseletsa e arohaneng ea 1.70A (16mm²); 2. Setulo sa ho tjheseletsa sa tšepe. | Nickel e hloekileng: 0.15mmNickel: 0.2mm | Betri ea selefounu, Betri ea polymer, Betri ea 18650 |

| HT-SW01A+ | 11.6KW | Pense e kopantsoeng ea ho tjheseletsa ea 1.70B (16mm²); 2.73SA e hatella hlooho ea ho tjheseletsa ea sebaka. | Nickel e hloekileng: 0.15mmNickel: 0.25mm | Betri ea 18650, 21700, 26650, 32650 |

| HT-SW01B | 11.6KW | Pense e kopantsoeng ea ho tjheseletsa ea 1.70B (16mm²); 2.73SA e hatella hlooho ea ho tjheseletsa ea sebaka. | Nickel e hloekileng: 0.2mmNickel: 0.3mm | Betri ea 18650, 21700, 26650, 32650 |

| HT-SW01D | 14.5KW | Pense e kopantsoeng ea ho tjheseletsa ea 1.73B (16mm²); 2.73SA e hatella hlooho ea ho tjheseletsa ea sebaka. | Nickel e hloekileng: 0.3mmNickel: 0.4mm | Betri ea 18650, 21700, 26650, 32650, electrode ea aluminium / koporo ea LFP |

| HT-SW01H | 21KW | Pene ea ho tjheseletsa e arohaneng ea 1.75 (25mm²); 2.73SA e hatella hlooho ea ho tjheseletsa ea sebaka. | Selae sa motsoako oa aluminium nickel: 0.15mmNickel e hloekileng: 0.3mmNickel: 0.4mm | Betri ea 18650, 21700, 26650, 32650, electrode ea aluminium/koporo ea LFP |

| HT-SW02A | 36KW | Pene ea ho tjheseletsa e arohaneng ea 75A (35mm²) | Koporo e nang le phallo: 0.3mm Selae sa motsoako sa nickel sa Aluminium: 0.2mm Nickel e hloekileng: 0.5mm Nickelage: 0.6mm | Letlapa la koporo, betri ea 18650, 21700, 26650, 32650, electrode ea aluminium / koporo ea LFP |

| HT-SW02H | 42KW | 1. Pene ea ho tjheseletsa e arohaneng ea 75A(50mm²) 2. Pene ea ho lekanya khanyetso ea Milliohm | Koporo e nang le phallo: 0.4mm Selae sa motsoako sa nickel sa Aluminium: 0.4mm Nickel e hloekileng: 0.5mm Nickelage: 0.6mm | Letlapa la koporo, betri ea 18650, 21700, 26650, 32650, electrode ea aluminium / koporo ea LFP

|

| HT-SW33A | 27KW | Sesebelisoa sa ho tjheseletsa sebaka sa pneumatic sa A30 | Koporo e nang le phallo: 0.3mm Selae sa motsoako sa nickel sa Aluminium: 0.3mm Nickel e hloekileng: 0.35mm Nickelage: 0.45mm | Letlapa la koporo, betri ea 18650, 21700, 26650, 32650, electrode ea aluminium / koporo ea LFP |

| HT-SW33A++ | 42KW | Sesebelisoa sa ho tjheseletsa sebaka sa pneumatic sa A30 | Koporo e nang le phallo: 0.4mm Selae sa motsoako sa nickel sa Aluminium: 0.5mm Nickel e hloekileng: 0.5mm Nickelage: 0.6mm | Letlapa la koporo, betri ea 18650, 21700, 26650, 32650, electrode ea aluminium / koporo ea LFP |

Livideo:

HT-SW01H:

HT-SW02H:

Qetello:

Se kaholimo ke selelekela sa molao-motheo oa ts'ebetso, ts'ebeliso, le litšobotsi tsa mechini ea ho tjheseletsa ea polokelo ea matla ea capacitor. Posong e latelang ea blog, re tla tsoela pele ho hlahisa litšobotsi le lits'ebetso tsamechine ea ho tjheseletsa libaka tsa pneumatic, ka kopo e lebelle ka thabo!

Haeba o na le lipotso kapa o ka rata ho tseba ho eketsehileng, ka kopo o se ke oa tsilatsila hoikopanye le rona.

Nako ea poso: Tshitwe-20-2023