Selelekela:

Rea u amohela hoMatla a Heltecblog ea indasteri! Jwalo ka moetapele indastering ya ditharollo tsa betri ya lithium, re inehetse ho fana ka ditharollo tse felletseng tsa sebaka se le seng bakeng sa bahlahisi le bafepedi ba dipakete tsa betri. Ka ho tsepamisa maikutlo haholo dipatlisisong le ntshetsopeleng, hammoho le tlhahisong ya disebediswa tsa betri,Matla a Heltece ikemiselitse ho matlafatsa indasteri ka ho fana ka lihlahisoa le lits'ebeletso tse ncha. Kamora lilemo tsa nts'etsopele, lisebelisoa tsa ho tjheseletsa libeteri li lula li ntlafatsoa, boleng ba ho tjheseletsa libaka le bona bo lula bo ntlafala. Empa hangata re bona mefuta e fapaneng ea ba tjheseletsa libaka fekthering e le 'ngoe ea tlhahiso hammoho, ba bapala karolo ea bona. Re tla tloha molao-motheong oa mefuta e fapaneng eamochini oa ho tjheseletsa libakaho utloisisa ts'ebetso ea bona.

Kopo:

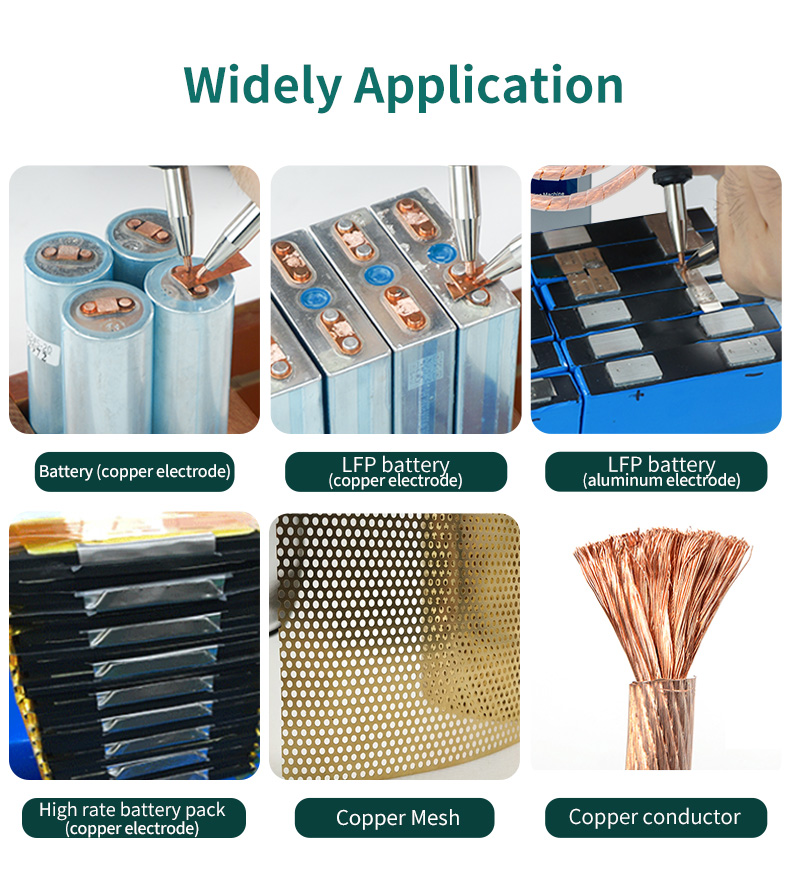

Ho tjheseletsa di-spot ho sebediswa haholoholo bakeng sa ho tjheseletsa di-plate tse tshesane. Tshebetso ena hangata e kenyeletsa ho tjheseletsa pele ho kgatello ho netefatsa hore dikarolo tsa mosebetsi di hokahane hantle; electrochemistry, e etsang motheo o qhibilihisitsweng le lesale la polasetiki sebakeng sa ho tjheseletsa; le forging ya ho tima motlakase, e dumellang motheo o qhibilihisitsweng ho phodiswa le ho kristale tlasa kgatello e tswelang pele ho etsalenonyeletso le teteaneng, le sa fokotseng, le se nang mapetso.

Mohlala,sesebelisoa sa ho weldera sebaka sa betrike sesebelisoa se ikhethileng se sebelisoang ts'ebetsong ea tlhahiso ea betri ho tjheseletsa lisele tsa betri le li-tab tse hokahanyang, tse nang le transformer, sistimi ea taolo, matlao a ho tjheseletsa, sistimi ea ho pholisa, jj. Transformer e sebelisoa ho fokotsa motlakase oa ho kenya le ho eketsa motlakase, sistimi ea taolo e laola nako ea ho tjheseletsa le motlakase oa ho tjheseletsa, 'me e sebelisa molao-motheo oa ho tjheseletsa ho hanyetsa ho hlahisa mocheso o phahameng sebakeng sa ho tjheseletsa ho fihlela ho kopanngoa ha tšepe, ka hona ho phethela ho tjheseletsa pakeng tsa sele ea betri le karolo e hokahanyang.

Tšobotsi ea Rona:

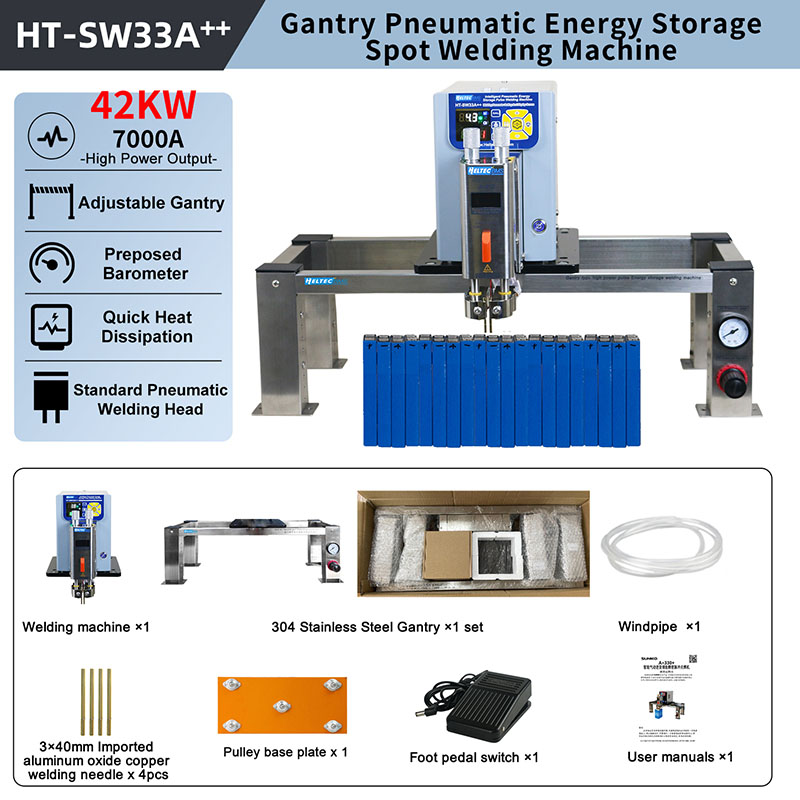

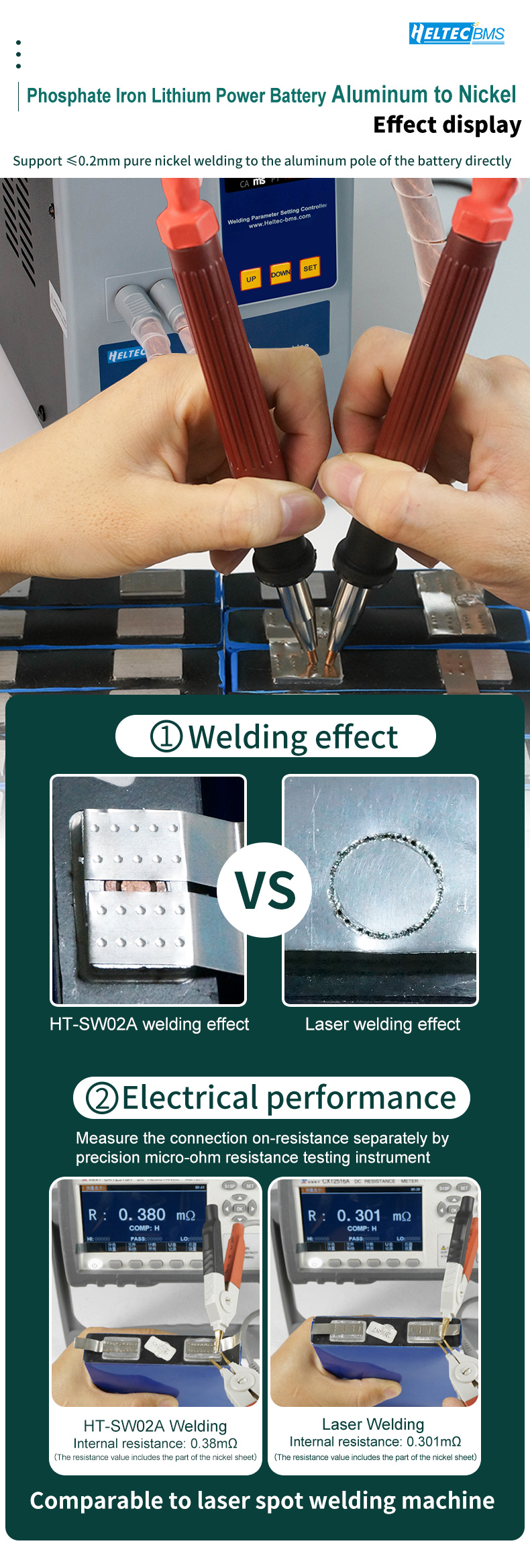

Re tsepamisa maikutlo ho theknoloji e tsoetseng pele ea ho tjheseletsa bakeng samechini ea ho tjheseletsa libaka e matla haholoHona jwale re ikgethile kamechine ea ho tjheseletsa ea polokelo ea matla ea capacitor, e kopantsoengmechine ea ho tjheseletsa ea pneumatic,Mechini ea ho tjheseletsa sebaka sa polokelo ea matla a pneumatic ea mofuta oa gantryjj. Ha ho bapisoa le ho tjheseletsa ka serame, lihlahisoa tsa rona li na le bokhoni bo matla ba ho tjheseletsa. Ha ho bapisoa le theknoloji ea ho tjheseletsa ka laser, leha e na le melemo ea ho sebetsa hantle le ho nepahala ho hoholo, lihlahisoa tsa rona li na le litšenyehelo tse tlase tsa lisebelisoa le litlhoko tse tlase tsa tekheniki bakeng sa basebetsi.

Qetello:

Se kaholimo ke kenyelletso ea molao-motheo oa ts'ebetso le ts'ebeliso ea mochini oa ho tjheseletsa libaka, blog e latelang re tla tsoela pele ho hlahisa litšobotsi le ts'ebeliso eamechine ea ho tjheseletsa ea polokelo ea matla ea capacitorlemochini oa ho tjheseletsa sebaka sa pneumatic, ka kopo e lebelle ka thabo!

Haeba o na le lipotso kapa o ka rata ho tseba ho eketsehileng, ka kopo o se ke oa tsilatsila hoikopanye le rona.

Nako ea poso: Pulungoana-15-2023